🔧 Power Up Your Precision!

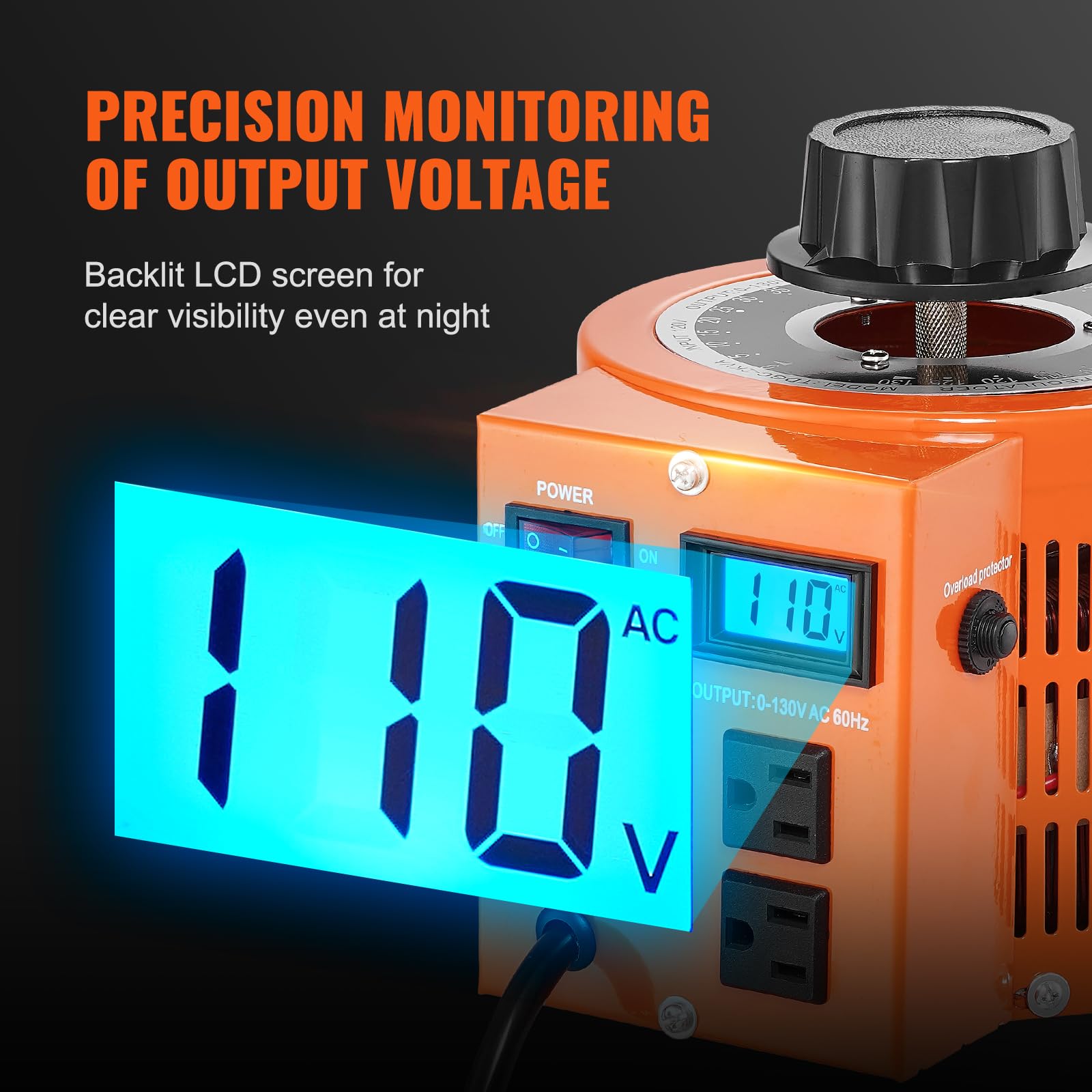

The VEVOR 2000VA Auto Variable Voltage Transformer is a versatile and robust voltage regulator designed for both home and industrial applications. With a maximum output of 15.3A and an adjustable output voltage range of 0-130V, it ensures precise control over your devices. Safety features include multiple fuses and a thermal control switch, while the durable metal casing and LCD display enhance usability and longevity.

| Specification Met | UL |

| Item Weight | 16 Pounds |

| UPC | 197988570240 |

| Manufacturer | VEVOR |

| Item Weight | 15.98 pounds |

| Product Dimensions | 8.7 x 6.7 x 7.7 inches |

| Item model number | TDGC2-2000VA |

| Manufacturer Part Number | 2000VA AVVT 15.3 Amp |

J**L

Mophorn 2KVA Transformer

I use this variable voltage transformer while repairing audio components. No problems with the unit and it is electrically quiet.

D**N

This is one big boi

Don't drop it on your foot, it's heavy AF. Check the dimensions—its not so much big in size as in size-to-weight. But that's to be expected with a 20 amp Variac. Also, the smaller models still weigh more than what you'd expect for the current that they carry. Not sure why that is, but probably has to do with voltage accuracy and thermal management. I felt like I should be able to get away with a much smaller, lighter device to manage voltage, but I'm sure they have valid reasons as materials are expensive, and most companies scrounge.This guy sits on my workbench right next to my DC bench supply and has come in handy for a lot of things. It's very accurate and sturdy, and the only issue I've had is that it's hard to read where the dial is from a distance. I used a label maker to print a black and white arrow for this, but it's still facing away from me if the voltage is set anywhere below 90-ish volts. The LED inside the power switch does seem to come in handy for me, and I may have to make an LED stack just to show voltage output. Maybe they should have a model that includes one; that would help.For the price, it's a steal. These things seem to appreciate with time, so it's probably not going to lose value any time soon.

G**R

Safety and reliability issues

First off, this is a very good value for an adjustable auto-transformer of this size. I have several 'name brand' units, but need an extra for a new project, and this was too inexpensive to pass up. And it worked fine after some modifications.Initially, as others have pointed out, grounding was done poorly in the unit as shipped. This was several months ago, so perhaps the've improved things since. There was only one ground wire attached to the outside shell containing the power switch, meter and outlets and it was not properly done. No 'star' washer nor did they remove the (rather substantial) paint from under the washer before attaching. Further, there was no 'copper' ground path to the major shell surrounding the autotransformer, itself. And given the good quality of the paint barriers between the two metal housings, it was clear there wasn't a sufficient 'ground' path between them. I added an additional #12 green wire to fix this, using a 'star' washer on the main frame. Grounding problem solved.After few months of service, the unit suddenly wasn't able to turn on. I had been using it at about half it's rated load (1.2kva) of the 2kva rating, so not really running it hard. But in spite of this rather light 50% load, the power switch housing melted and freed the power pin that runs to the fuse. Dead.Fortunately, Digikey carried a near replacement (EG5597-ND) with rating to 20A 115VAC, cost $1.94 in single quantity.) Switch is from E-SWITCH and is solidly built. It did require a bit of filing of the opening in the metal shell, as the as-built switch was about .5mm smaller in each dimension. After this mod, the unit was 100% back in commission.I suggest you avoid the urge to purchase one of the similar switches on Amazon as the suppliers all seem to carry the same cheap switch as was in the unit initially. Using a non-thermosetting plastic was a bad idea because a little warmth caused the plastic to 'flow' until contact starting heating due to resistance caused by the now, poor connection. Stick with a switch that a UL label (the original unit does not.)I should also point out that when making the new switch connection, I avoided soldering wires to the switch, as that's a no-no with a 2kva appliance. Crimped spade-lug quick-connects were added to the wires and these were used to make the connection to the switch. I was tempted to do this same to the socket connectors, but saved that for 'next time.' And I *will* remove and replace the 'hot snot' hot-melt glue that used to anchor the cord and sockets to the metal shell. This isn't an automatic 'safety' issue, but it's just gross.Otherwise, this appears a very fine, inexpensive, and so far, reliable device. I may purchase another but will definitely apply these modifications before use. And hopefully the manufacturer will take these suggestions and make the necessary safety mods to their future units. "Name brand' units go for at least twice what this unit cost, so there is a bit of room to improve and still have a great price.

A**H

Power Up

As a builder of old-school all-tube guitar amps, I have been using variac units for many years to carefully test my newly built amp head units. I relied heavily on a couple older US built variacs that I bought online, they served me well. I thought of them as being better than any similar Chinese units on the market today.A couple weeks ago, my latest build failed to power up when supplied by my trusty 60-year-old Connecticut built Variac. Initially I assumed builder (or at least component) error.But on further reflection, I felt absolutely certain I had not made a mistake. This led me to roll the dice (not smart) and bypass the variac altogether.My amp build worked like a charm, which told me that my trusty American made variac had failed.Instead of going in search of another relic from the past, I decided to try this Variable Voltage Transformer from VEVOR, sold on Amazon. At the time there was a sale price discount to be had, so I bought 2 units, since I generally build and test my amps both in New England, as well as in the Southeast.I will start with the negative, of which there is very little. If you are accustomed to the solid feel of the potentiometer on an old American variac, you will find this to be slightly less awe inspiring.That's it in total. Slightly less inspiring.I received both units in the same delivery, so I unboxed and tested them side by side. Believe me, I was ready to return them both if either failed inspection.The units are heavy, even heavier than my old American made ones. To me that suggests substantial iron and wire.Unlike my antique units, these variacs have digital output meters. In order to see if the built in displays were at all accurate, I used my Fluke 117 to monitor the voltage output. Fluke is considered by many to be the best digital multi meter available.In both cases, the Fluke meter confirmed that each new VEVOR variac was spot on for accuracy.If there are interior build issues that need to be addressed, as other reviewers have suggested, I will certainly do that. Such improvements should not prove too difficult to suss out or perform for anyone who would use a variable voltage transformer in the first place!So, thanks China, for providing what no American company is able to build or ship! I'm sold.

S**S

Great tool for the electronic work bench, don't operate without one!

The built in volt meter does not always match actual voltage but using an external volt meter will solve that. I is great to be able to adjust the input supply voltage as needed. I run a split off through a full wave Rectifier with some filtering and I have 0 to 150 volts DC to supply most any device under test. Plenty of current.

Trustpilot

1 month ago

3 weeks ago