🚀 Elevate Your 3D Printing Game!

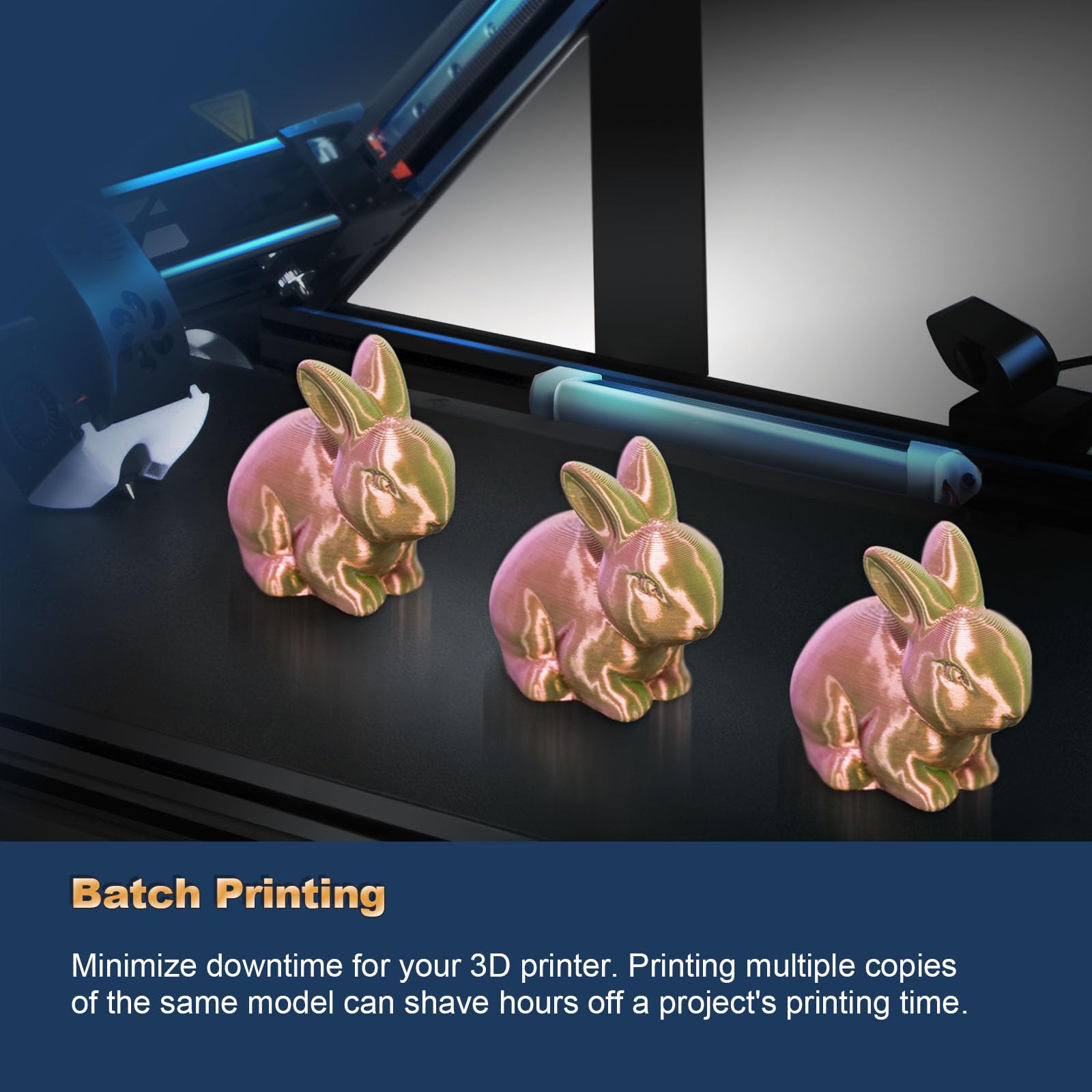

The Official IdeaFormer-3D IR3 V2 Conveyor Belt 3D Printer features a 250×250×∞mm printing area with an upgraded metal conveyor belt for enhanced layer adhesion. It boasts one-click auto calibration, Klipper firmware for high-speed performance up to 400mm/s, and supports a variety of filaments, making it ideal for both large-scale projects and efficient small-part production.

N**Z

Great Printer,

Update 5-7-25Have had some issues but the support team is very responsive and helpful. Overall I am very satisfiedPrints excellent write out of the box. Both large and small parts print great, the leading edge can have some issues but that’s nothing that cant be tweaked.Some issues I encountered:Windows immediately deletes the executables flagging as malware. I ended up running this on my VM so I could completely turn off defender.Instructions are a bit unclear, for both assembly and software. I had a couple of issues, some of which were user error.Setup hardware issues: I ended up forgetting the feed sensor which intermittently threw a duplicate canbus error. The cable was jammed in the roller on the underside(I forgot to plug it in because it was tucked underneath) this didn’t allow the belt to move freely. After about 3 prints that ran over themselves I figured that out.Setup Software Issues:You use a combination of the two to print. The idea software is only used for slicing and exporting gcode. It appears to be setup for a different brand of printer. Be sure to follow the instructions to import the idea printer carefully. You will see options to connect a printer but this software is only used to export the gcode. I got lost trying to connect a printer for quite a bit.The web GUI (fluidd):You get here by navigating to the IP address of the printer. It is here that you can upload your gcode and actually print the file. You can also adjust your print settings in a lag free environment (the HMI on the printer can be very laggy). You can view your print with the camera either at home or away with port forwarding. When accessing from the outside, you will be prompted to login.Overall,This printer works extremely well. I am thoroughly impressed. As a complete noob to 3d printing, this has made my first projects easy. The prints come out solid without tweaking(minus the leading edge). Would definitely buy again

C**E

Great belt printer

I have been printing for several years, this is my first belt printer. I was very impressed with the quality of the printer. It is very well made, all metal. Assemble was quick and easy. Their video needs to be slowed down to see details but easy to do on youtube. I appreciate them providing a spare nozzle and a small roll of filament. Was able to print something as soon as assembled. Auto level is a dream, one button. Support has been off the charts via email always very helpful. Printing on a 45 degree angle takes some thought, but the preview in ideamaker makes it easy to visualize. I would buy again.

C**R

Okay for making one thing, perfect for making thousands of things.

If you are looking to mass-produce parts with a 3D printer, look no further. This is the best option on the market for turning filament into objects, with zero human intervention. There are plenty of printers that will be faster, larger, or have a slight advantage in quality. However, the bed of this printer allows you to print uninterrupted, limited only by your filament spool size and how many things you want to print. I have personally run the machine for a week straight on one large roll of filament, with no issues. Make sure that you use the Y-axis offset macros that are included in the firmware, along with a piece of paper, to make sure you get the nozzle the right distance from the bed. Too close to the bed, and the PEI surface will suffer extreme wear. Get the nozzle distance right, and parts stick well while popping off easily once cooled.This machine runs Klipper, with a few tweaks to accommodate the different mechanical setup of this machine. I upload parts, and then put them into the print queue. The included webcam make monitoring prints easy, and the very rare print failures are simply pushed along the bed, instead of causing nozzle crashes like traditional machines.A downside of this machine is that almost all objects you can download from model repositories are made for traditional printers. The 45 degree tilt of the gantry causes overhang issues with models that would be easy on a regular machine, especially cone shapes that go from a smaller to larger diameter as the part prints. For best results, I would advise designing your own parts to take the unique print geometry into account.In conclusion, who is this for? If you are looking for your first printer, I would look elsewhere to get your feet wet. If you want to print minis, or objects that other people have designed, I would look back to traditional printers. HOWEVER, if you have an idea that you want to make hundreds of times, this machine is your first, best choice. The combination of reliability, efficiency, and interaction-free serial production can't be beat in this use case. Etsy stores, small businesses, and medium businesses looking to add a reliable, production-level printing capability to their arsenal are this machine's bread and butter.

D**W

Good machine, Easy setup, Fast and responsive customer service

When the product arrived damaged, Ideaformer was fast and helpful in assisting me. I returned the machine and received a second machine which worked well and was easy to set up. Alignment of the extrusions is very good. Leveling and setup are easy. This machine has the highest print quality of any belt printer currently available. It is also the only belt printer I know of with Klipper and input shaping.Overall a very good product. This design was likely very difficult to execute, and they did a very nice job.

S**C

Well built, great performance, and opens new possibilities in my 3D printing!

This printer is great. Right out of the box, it handled a Benchy and two 46-inch-long pieces perfectly. I have a variety of upcoming projects that require long plastic parts, and the IR3 V2 is the only belt printer worthy of consideration in 2025. It arrives well-packed in a box with custom-cut foam. Assembly is minimal, and everything is well-built. Even the XY bearing blocks/linear rod carriers are milled aluminum, whereas others use sandwiched plates or injection-molded plastic. Overall, the printer has performed great, is well-built, and has opened up new possibilities in 3D printing for me.

Trustpilot

1 month ago

1 day ago