Customer Services

Copyright © 2025 Desertcart Holdings Limited

🔧 Cut like a pro, every time — precision meets power!

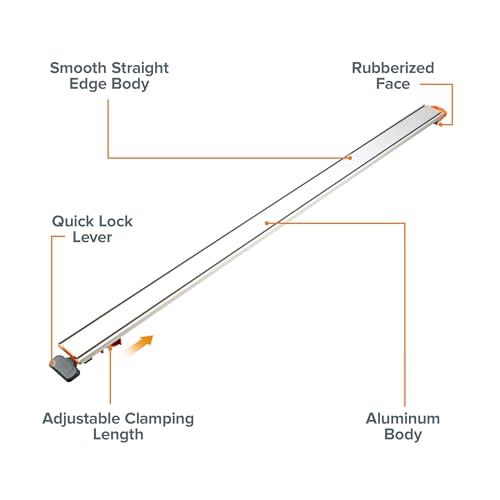

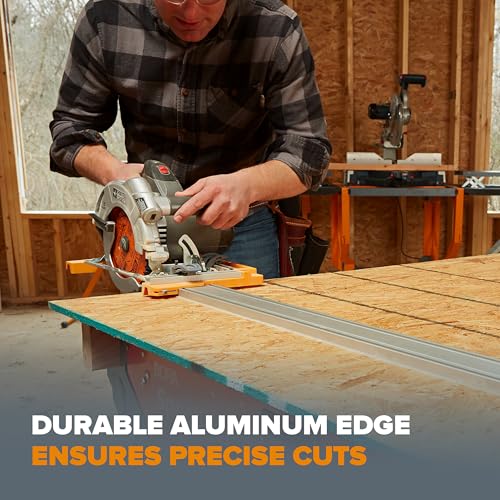

The BORA 50" NGX Clamp Edge is a 50-inch aluminum straight cut guide designed for circular saws, offering professional-grade precision with a quick-lock ergonomic clamp and built-in T-track for enhanced customization. Ideal for cutting plywood sheets and large materials, it combines durability and ease of use to deliver flawless, slip-free cuts, making it an essential tool for woodworking pros and serious DIYers.

| ASIN | B08146J2T8 |

| Are Batteries Included | No |

| Brand | BORA |

| Color | multicolor (black / white) |

| Customer Reviews | 4.1 4.1 out of 5 stars (926) |

| Date First Available | November 27, 2019 |

| Included Components | BORA 50" NGX Clamp Edge |

| Item Weight | 907 g |

| Material | Aluminum |

| Model Number | 544050 |

| Name List for Name Plates | Adjustable, Round |

| Product Dimensions | 7.62 x 5.08 x 147.32 cm; 907 g |

D**G

Funciona perfectamente con la guía para sierra caladora de BORA (542009) realizando cortes rectos cada vez

D**D

As described

M**R

bonne outil

E**G

I got this with the saw guide, to make an "affordable track saw". Works pretty darn well for that purpose, once you get the edge guide aligned with your saw. BIG TIP: The clamp always seemed to be "sticking". Sometimes it would slide easily, but often it would jam up and stop sliding at all. It took forever to figure out the trick. Now it slides easily all the time. The trick is this: * The orange part of the clamp has two little tabs sticking out at the back end. * I had no idea what they were for, and none of the instructions mentioned them. * You put the heel of you palm against the back of the gray handle (in the "open" position), and then pull back on those tabs with your fingers, as though pulling on a hypodermic needle. * Voila! The internals of the clamping mechanism (whatever they are) COMPLETELY disengage, and the clamp slides freely in its track. Important Notes: 1) In the pictures, the "edge guide" looks like thin tape that could go anywhere. It's not. It's a nice, thick piece of plastic, with adhesive on one edge so it is ready to apply, and there is cut-away on the bottom of the clamp to attach it to, so it works well. 2) You NEED the edge guide. If you use the clamp for cutting sheet goods, you darn well want that edge guide in place. It is the ONLY good way to align the clamp for cutting. (There are blade-markers on the saw guide, but they're not really useful for lining up the cut when the saw is on the guide. (If you take the saw off, they may work. I didn't.) 3) To attach the edge guide, it's best to remove the clamping mechanism. (Easily done by taking out two screws. The instructions don't say that (they could use improving), but it's pretty easy to figure out there is no way to attach the edge guide the full length of the clamp, until you do. 4. The tape on the edge guide doesn't QUITE go to the end. It's maybe 1/4" short, but there is an inch of extra tape, so do yourself a favor and cut off the end of the guide where there is no adhesive, before you start applying it to the clamp. That will remove the slight tendency of the edge to lift up--something I may have to trim off, eventually. 5. Don't bother with the T-Square attachment! Total waste of money, if you're using the clamp as a track-saw. (For details, see my review of that attachment. It works fine when it makes a "T", but it has to be in an "L" configuration to work with your saw. And in that configuration, it fails miserably.) 6. Now that you know you CAN'T depend on the T-Square for alignment, and you MUST have the edge guide in place, do yourself a favor and mark BOTH sides of the panel you're cutting. Then put the clamp in place, and cut away. You'll save yourself the half-panel I ruined before I figured out those steps. 7. But there is still ONE MORE PROBLEM to solve, if your saw is like mine. The edge guard projects 1/2" beyond the edge of the clamp. The instructions for mounting the saw to the saw plate don't SAY to put the blade as close as possible to the edge of the plate, but they should. What they DO say is to make sure the blade guard is free to move. That's a darn good idea. BUT... On my Ryobi saw, "reasonably close" puts the blade 3/4" from the plate. The blade guard is pretty thick where it is close to the plate, so I can get it the saw MAYBE 1/8" closer, while still being able to move the guard. I KNOW I can move it 1/16" of inch closer. And I MAY be able to move it 1/8". But I NEED it to be a full 1/4" closer, for the edge-guide to be of any use. In "short" (pun intended), the edge-guide is 1/4" too short for use with my Ryobi circular saw. Will it work with other saws? Don't know. But I would check the width of yours. If your blade guard is more than 1/8" from the edge of the blade, it won't work. There is a WORKAROUND, though. So check your saw before installing the plastic strip that comes with the clamp. If it won't be wide enough, double-sided carpet tape and a strip of linoleum are the perfect size. Here's the procedure: a) Get a linoleum remnant from your nearest big box store, along with double-sided carpet tape. b) Cut a 2" strip of linoleum the length of your clamp. c) Put double-sided carpet tape in the groove under the clamp. d) Turn the clamp right-side-up and use your razor-knife to trim the excess tape. e) Turn the clamp over again, peel the backing from the tape, and put down the strip of linoleum, shiny-side pressing into the tape. f) Find a nice long piece of wood you can cut the end off, and do it. Voila! You now have a perfectly-trimmed edge guide!

J**N

I have been using this guide for a few months. One of my best and "can't live without it" tools. Someone mentioned that it was hard to slide the "lock". I found a trick. If it is stuck, just push the "lock" UP. If this still doesn't work, slide the "lock" back and push it towards the wood / board again (remember to keep on pushing UP). Some people mentioned about it was not an accurate (exact 90 degree) cut. You still have to mark the board / wood on both the start and the end. Then, line up this guide based on these two points.

Trustpilot

1 month ago

1 month ago